What is finished goods inventory? Definition, formula, and calculation

- admin

- 0 Comments

The employer will grade and level the surface and will then place down foundation forms to border in cement. Wire mesh or rebar is placed in the forms and cement or concrete is poured which is later troweled. This classification also applies to the use of asphalt to pave parking lots and courts. The asphalt is applied to the ground and the employer then spreads the asphalt with a rake. The painting of traffic lines in parking lots after the paving or repaving is completed by the same contractor is inclusive under this classification.

- Let’s take a deeper dive into how inventory becomes finished goods and how you can make sure your business is fully prepared for sale every step of the way.

- Rather, your ideal finished goods inventory level should be the minimum amount you can have on hand while still meeting customer demand.

- In that sense, it’s similar to the COGM calculation, but it doesn’t take in account WIP inventory.

Company

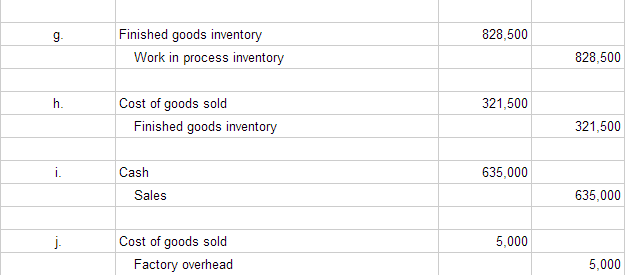

The previous year’s finished goods may include stock carried into the new period, contributing to ending inventory and impacting total manufacturing costs for the same period. You order thousands of aluminum sheets with which to make the cans, which is considered raw materials inventory. It’s not until the sheets are put on a production line that they become work-in-process inventory, and when they’re made into cans, then they are finished goods inventory. As savvy business owners and supply chain management enthusiasts, it’s crucial to understand the ins and outs of inventory management, and finished goods inventory is no exception.

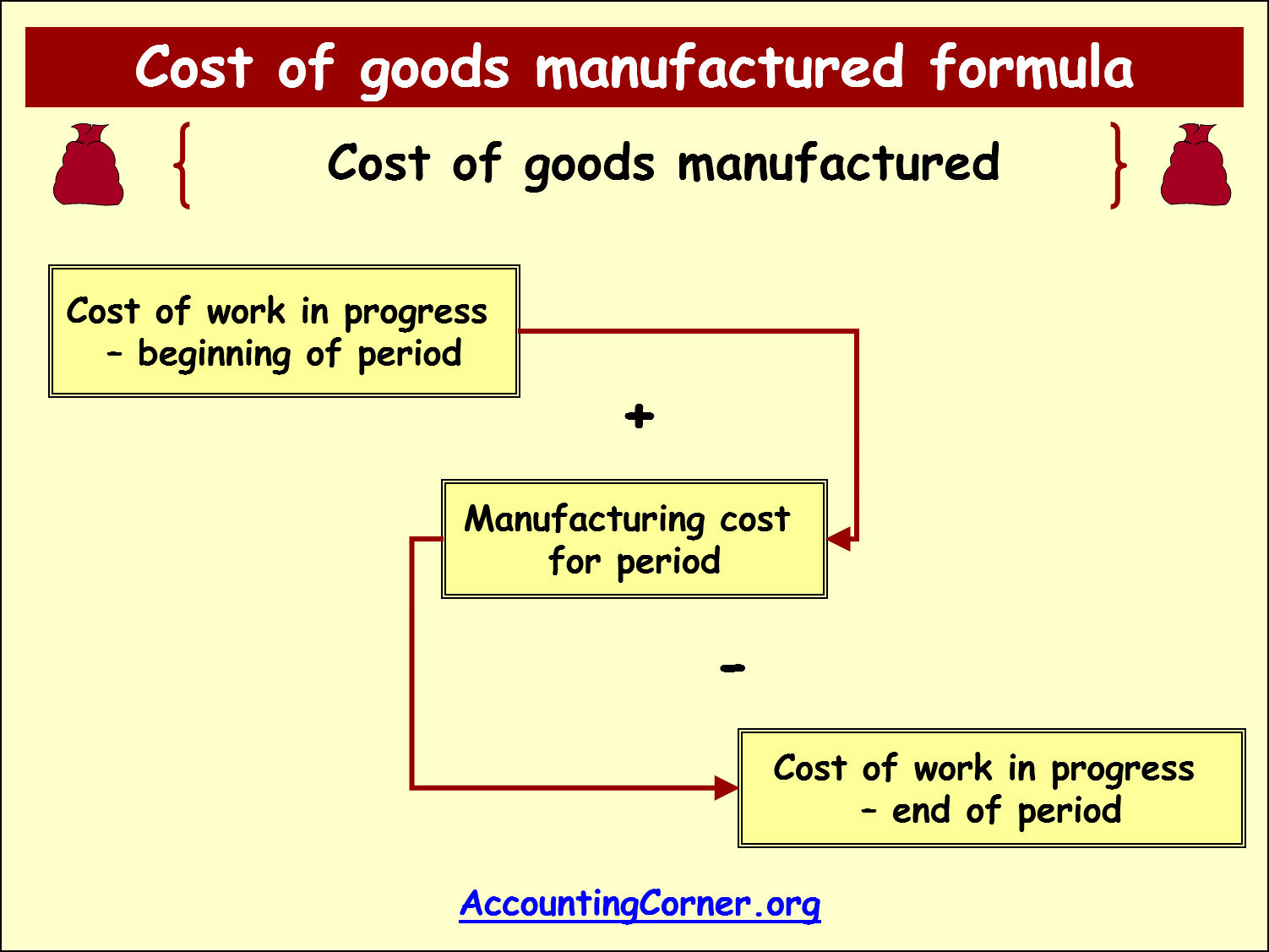

How to calculate finished goods inventory?

If the insured is classified as Code 5606 and also has this classification exposure, this classification shall apply even if the Code 5606 exposure is greater. This classification also includes the care and maintenance of each grave as well as general maintenance operations. Additionally, the maintenance of a mausoleum is considered incidental to the operation of the cemetery and is included under the scope of this classification. Salespersons assisting customers in the office who also show gravesites around the property are inclusive under this classification. This classification also applies to employers engaged in manufacturing mica goods made from mica and mica preparing. Mica is a silicate mineral such as muscovite, the most common type of mica in the mica group which readily separates into thin, pliable leaves due to its crystalline structure.

Custom Clothing or Tailor Shop – Alterations – No Mass Mfg., Dry Cleaning or Laundering

Raw materials such as drawn wire (copper and aluminum) and insulating material such as rubber, plastic, cotton thread, paper, vinyl, lacquer and enamel are purchased from outside suppliers. Various gauges and types of wire can be insulated using various types of insulating materials. The most common types of wire that are insulated are copper and aluminum. A manufacturer may purchase raw materials that will become part of finished goods accounting the finished product without paying sales tax by issuing Form ST-120, Resale Certificate, to its supplier. Flowspace understands that managing finished goods inventory is a critical aspect of e-commerce success. That’s why Flowspace pairs powerful software with a flexible nationwide fulfillment network to support growing ecommerce brands as they optimize their supply chains and improve work in process inventory levels.

Finished goods inventory management

Use manufacturing analytics to monitor key metrics such as inventory turnover, sales trends, and product performance. Analyzing this data will help you make informed decisions about inventory stocking, reordering, and discontinuing slow-moving items. These KPIs help evaluate finished goods inventory performance and guide data-driven decision-making for inventory management.

What is a finished goods inventory?

This classification also applies to manufacturing cigarette filters exclusively. This involves the use of converted cigarette-making machinery that rolls, crimps, and forms paper and cellulose acetate fiber. A plasticizer material, in turn, is sprayed into the filters, followed by a drying process. Finished goods inventory management is the process of keeping track of the goods you have ready and available to sell to your customers. It helps you understand how much value your business holds in stock, meet consumer demand for your products, and avoid wasting money on excess stock or storage space.

When the candles attain the desired size and shape and have cooled, they are taken from the dipping cycle. After cutting the wicks, the candles are put into self-fitting end molds to shape the base. Flowspace’s system also provides real-time alerts when finished goods inventory levels dip below a predefined threshold. Additionally, our predictive forecasting helps you anticipate future demand fluctuations, allowing you to proactively adjust your inventory levels and ensure you always have the right amount of the right products in stock. Flowspace’s advanced analytics tools leverage real-time data and historical sales trends to generate actionable insights. This allows you to forecast demand with greater accuracy, optimize finished goods inventory levels, and minimize the risk of stockouts or overstocking.

Key features include tracking finished goods inventory, forecasting demand, and offering alerts for inventory turnover. A finished goods inventory budget considers the direct raw materials, direct labor, and overhead costs. In that sense, it’s similar to the COGM calculation, but it doesn’t take in account WIP inventory. All it’s doing is assigning a value to every unit produced based on raw materials, labor, and overhead. Assigning WIP inventory may be disregarded if the manufacturing process is short.